- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

All Purpose Adhesive

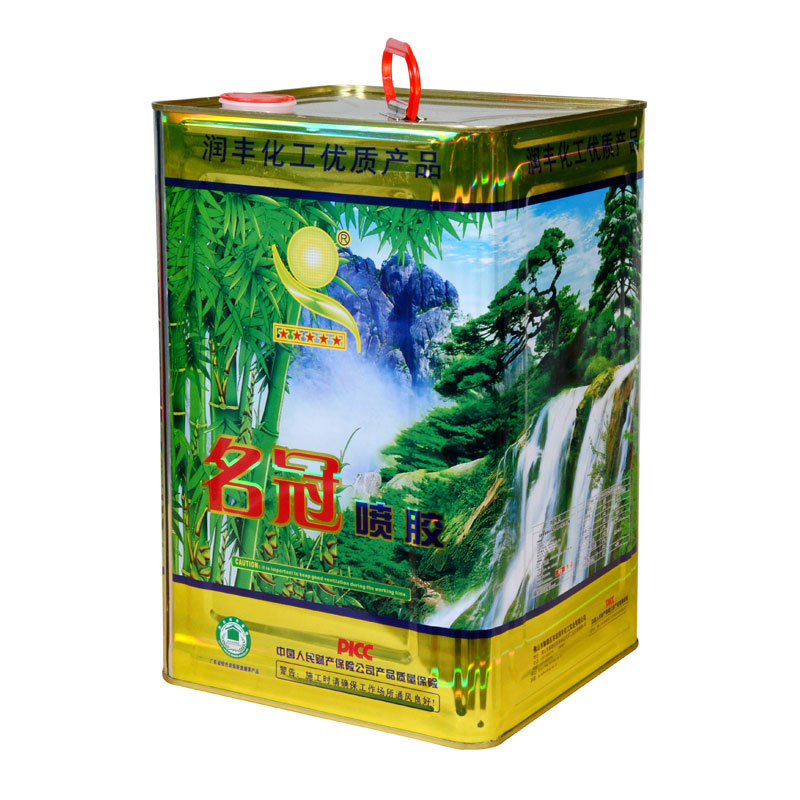

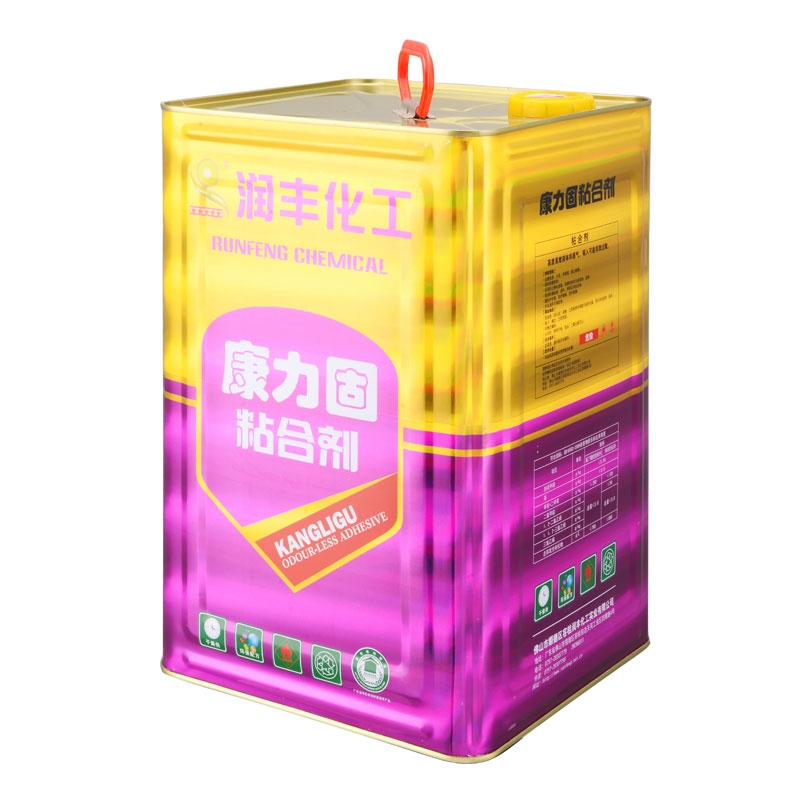

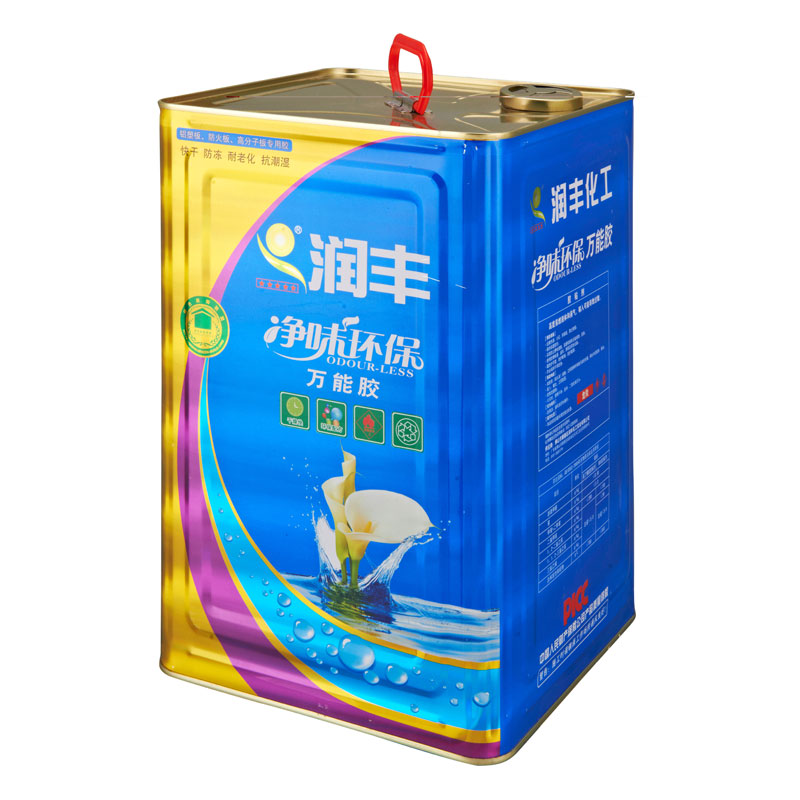

All Purpose Adhesive products from Runfeng supplier are adhesives designed for the luggage manufacturing and repair industries, with a wide range of bonding and excellent performance. The following is a detailed introduction to all purpose adhesive products.

Send Inquiry

All Purpose Adhesive adhesive is a multifunctional solvent-based adhesive, usually containing ingredients such as chloroprene rubber, supplemented with solvents and other additives. It is widely used in the luggage industry for its strong bonding and wide applicability.

Product Features

Wide bonding range: all purpose adhesive can bond a variety of materials, including leather, artificial leather, nylon cloth, non-woven fabrics, EVA, medium-density fiberboard, sponge, etc., to meet various needs in luggage manufacturing and repair.

Strong bonding: The adhesive has excellent bonding strength, which can ensure a firm bond between the various parts of the luggage and improve the durability and service life of the luggage.

Quick drying and curing: all purpose adhesive can usually dry and cure quickly after application, improving construction efficiency and shortening production cycles.

Environmental protection: With the improvement of environmental awareness, all purpose adhesive products on the market are also paying more and more attention to environmental protection performance, and products with low VOC (volatile organic compounds) emissions are gradually becoming mainstream.

Usage scenarios

All purpose adhesive is suitable for various bonding needs in the manufacturing process of luggage, such as bonding between leather and leather, leather and cloth, cloth and cloth, as well as repairing and reinforcing luggage parts.

Product types

Depending on the specific formula and purpose, there are many types of all purpose adhesive products. Common all purpose adhesives include neoprene type, polyurethane type, etc. Different types of adhesives may differ in bonding strength, weather resistance, environmental protection, etc. Users can choose according to specific needs.

Precautions for use

Surface treatment: Before bonding, ensure that the surface of the bonded material is clean, dry, free of oil and impurities to improve the bonding effect.

Glue application amount: The amount of glue application should be reasonably controlled according to the type and thickness of the bonded material to avoid excessive or insufficient bonding or waste.

Air-drying time: Some all purpose adhesives require a certain amount of air-drying time to volatilize the solvent and increase the viscosity. The specific air-drying time should be carried out according to the product instructions.

Construction environment: The all purpose adhesives contain volatile solvents. During construction, the air should be kept unobstructed and should not be close to open flames or high temperatures.

Storage conditions: It should be stored in a cool, dry place away from fire and children, and avoid deterioration caused by direct sunlight and high temperature environment.