- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

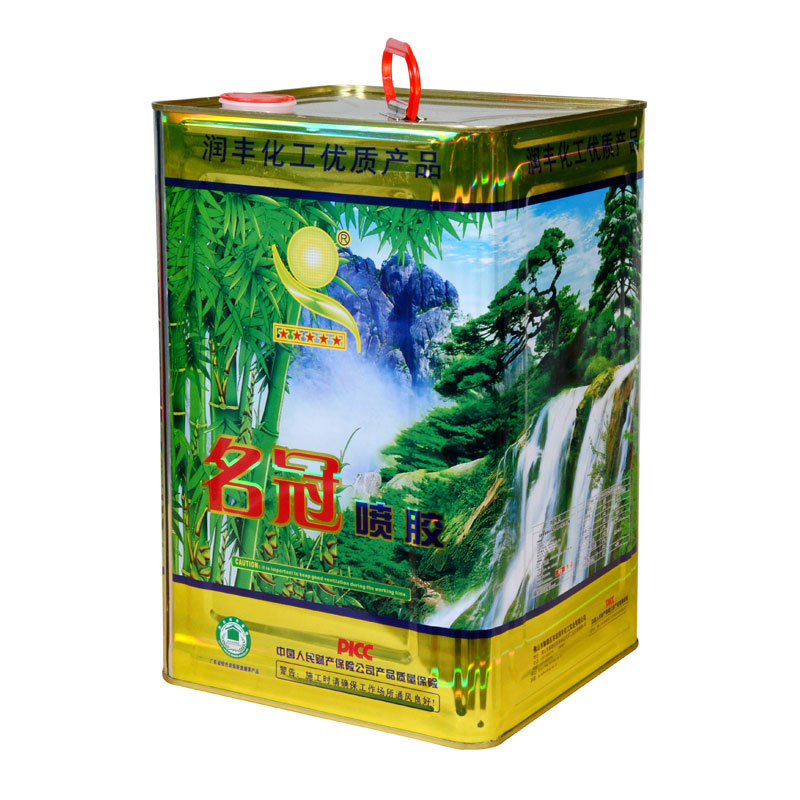

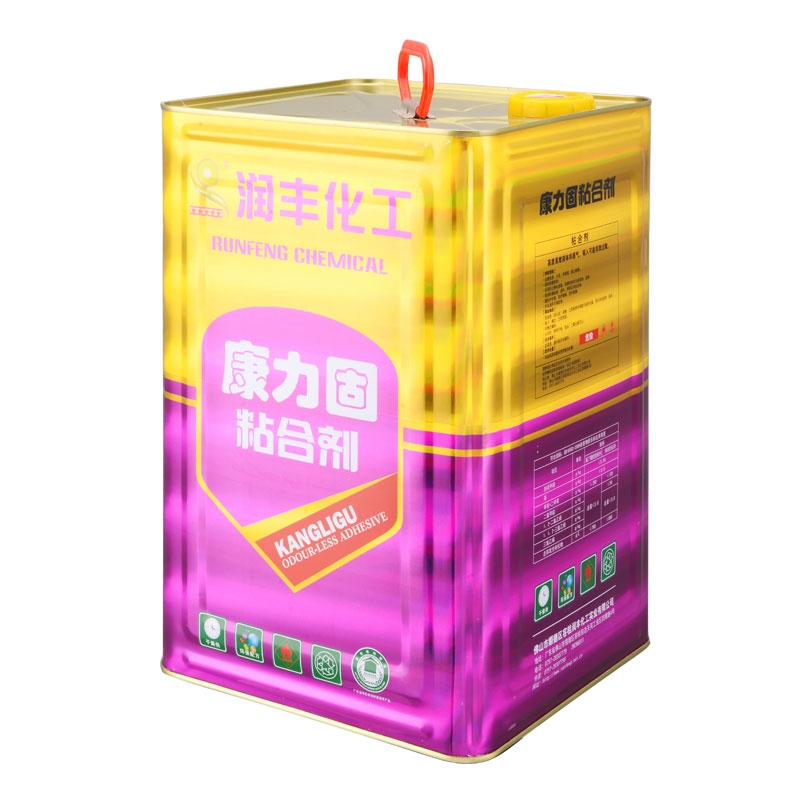

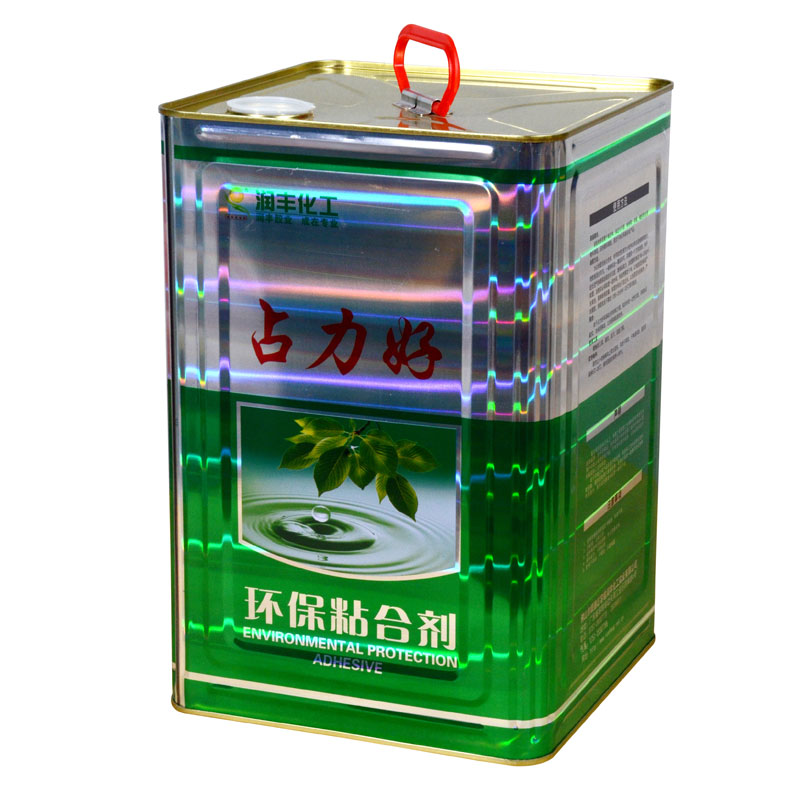

Neoprene Glue for Shoe

Neoprene Glue for Shoe produced by Runfeng Factory has excellent adhesion, aging resistance, water resistance, oil resistance and chemical medium resistance, and is very suitable for the production and maintenance of footwear products.

Send Inquiry

Neoprene Glue for Shoe is an adhesive specially used for shoe manufacturing and repair. Its main component is chloroprene rubber (CR), also known as chloroprene rubber or new flat rubber.

Neoprene Glue for Shoe is an adhesive made of chloroprene rubber as the main raw material and processed by special technology. Neoprene is an elastomer generated by α-polymerization of chloroprene (i.e. 2-chloro-1,3-butadiene) as the main raw material. It has excellent adhesion, aging resistance, oil resistance and chemical corrosion resistance.

Product Features

Wide bonding range: Neoprene shoe glue can bond a variety of materials, including leather, rubber, plastic, fabric, etc., and is particularly suitable for bonding shoe materials.

High bonding strength: The adhesive has the characteristics of large initial adhesion and rapid strength building, which can ensure a firm bond between the various parts of the shoe.

Good aging resistance: Neoprene has excellent aging resistance and can maintain a stable bonding effect during long-term use.

Oil resistance and chemical corrosion resistance: Neoprene shoe glue has good resistance to grease and chemical solvents, and is suitable for the use of shoes in complex environments.

Easy to use: Neoprene shoe glue usually has good fluidity and spreadability, which is convenient for construction personnel to operate.

Product types

There are many types of neoprene shoe glue products. According to the specific formula and use, they can be divided into solvent-based, emulsion-based and solvent-free liquid types. Among them, solvent-based neoprene shoe glue is divided into mixed type and grafted type, which are widely used in shoe manufacturing and maintenance industries.

Precautions for use

Surface treatment: Before bonding, ensure that the surface of the bonded material is clean, dry, free of oil and impurities to improve the bonding effect.

Glue application amount: The amount of glue application should be reasonably controlled according to the type and thickness of the bonded material to avoid excessive or insufficient bonding or waste.

Air-drying time: Some neoprene shoe glues require a certain air-drying time to volatilize the solvent and increase the viscosity. The specific air-drying time should be implemented according to the product manual.

Construction environment: Neoprene shoe glue contains volatile solvents. During construction, the air should be kept unobstructed and it should not be close to open flames or high temperatures.

Storage conditions: It should be stored in a cool, dry place away from fire and children, and avoid deterioration caused by direct sunlight and high temperature.